Prismlab umgca wokuvelisa indibano ezenzekelayoyenzelwe ukuba isetyenziswe ekuqhubeni nasekuveliseni izilungelelanisi ezicacileyo.Enokuthi iqonde ukwenziwa kolungelelwaniso olucacileyo kwi-thermoforming, ukuphawulwa kwelaser kunye nokusikwa ngokuzenzekelayo, yonke impumelelo yokusebenza iya kwandiswa kakhulu kwimveliso yobuninzi.

2. IParameter yeTechnique yeZixhobo

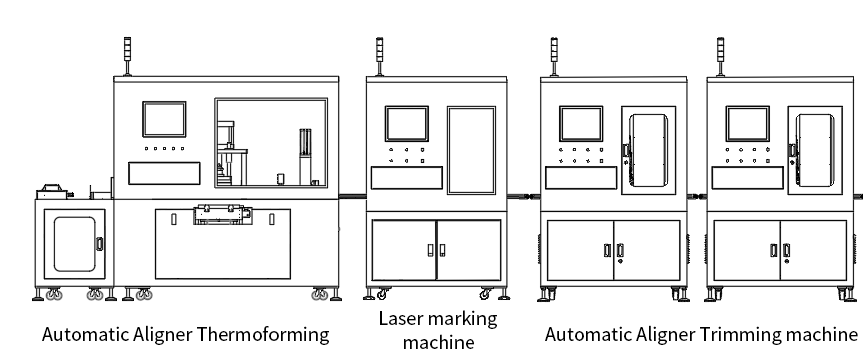

2.1 Umzobo wokuSebenza woMveliso

| Hayi | Igama lemveliso | Ubungakanani | Ubunzima | Amandla | I-Voltage |

| 1 | I-Automatic Aligner Thermoforming | 2.7*1.1*2 m | 800KG | 3.5KW | 220 V |

| 2 | Umatshini wokumakisha weLaser | 1.4*1.1*2 m | 400KG | 2.5KW | 220 v |

| 3 | Umatshini wokucutha ulungelelwaniso oluzenzekelayo | 1.3*1.1*2 m | 600KG | 3.5kw | 220 v |

| / | / | / | / | / | / |

3.Iiparamitha zeTechnical ze-Automatic Aligner Thermoformingmachine

1) Umgangatho wobushushu obulawulekayo: 150℃ -400℃s, ifoyile yafudunyezwa ngokulinganayo.

I-2) Ukufudumeza ukusebenza kakuhle: 3) Ukulawulwa kokwenza uluhlu loxinzelelo: I-1-10 Bar

4) Ukusebenza kakuhle kokwenza (ixesha elinye lokugqiba ukwenza): ≤15 imizuzwana

5) Ugqwesileyo ngokuhambelana

6) Izinga elingalunganga lokuqulunqa (ireyithi yokusebenza kwakhona): <1%

7) Ngomsebenzi wokuchonga umlinganiswa oyimodeli

I-4.Iiparamitha zezobugcisa ezisebenzayo

1) Izinga lokuqaphela okubonakalayo> 99%

2) Ixesha lokuqaphela okubonakalayo ≤0.2 imizuzwana

3) Isantya sokuqaphela i-laser yokumakisha ikhowudi ye-QR> 99.9%

4) Laser ixesha elilodwa lokubhala ikhowudi < 2 imizuzwana

5) Isantya esinesiphako sekhowudi yelaser sisondele kwi-0

I-5.Iiparamitha zeTechnical zoMshini wokuNciphisa ulungelelwaniso oluzenzekelayo

I-1) Umda wolungelelaniso ocacileyo emva kokuqhawula uhambelana nomgca wokuqala wokulinganisa, kwaye ukuchaneka ngu <0.3mm

2) Ixesha lokusebenza lokucheba ulungelelwaniso olulodwa olucacileyo: 3) Akukho kuphazamiseka kwinkqubo yokulungisa

4) Emva kokucheba, izinga le-edge burr lolungelelaniso olucacileyo lingaphantsi kwe-2%

5) Ukunciphisa kakubi (ukusebenza kwakhona) izinga: <1%

I-6) Ukubonelela ngezixhobo ezixhasayo kunye nesofthiwe yokusombulula ukuveliswa ngokuzenzekelayo kwemigca yokuqhawula kunye nemisebenzi yokulungiswa kwezandla;

7) Ukubonelela ngezixhobo ezixhasayo kunye nesoftware ukusombulula umsebenzi wokuvelisa imilo yesiseko yokunquma kunye nokubeka;

I-8) Ukubonelela nge-API interface, ukusombulula indlela yomgca wokunciphisa isiko, isixhobo se-Angle setting function;

Ixesha lokuposa: Oct-10-2022